What is flex in PCB?

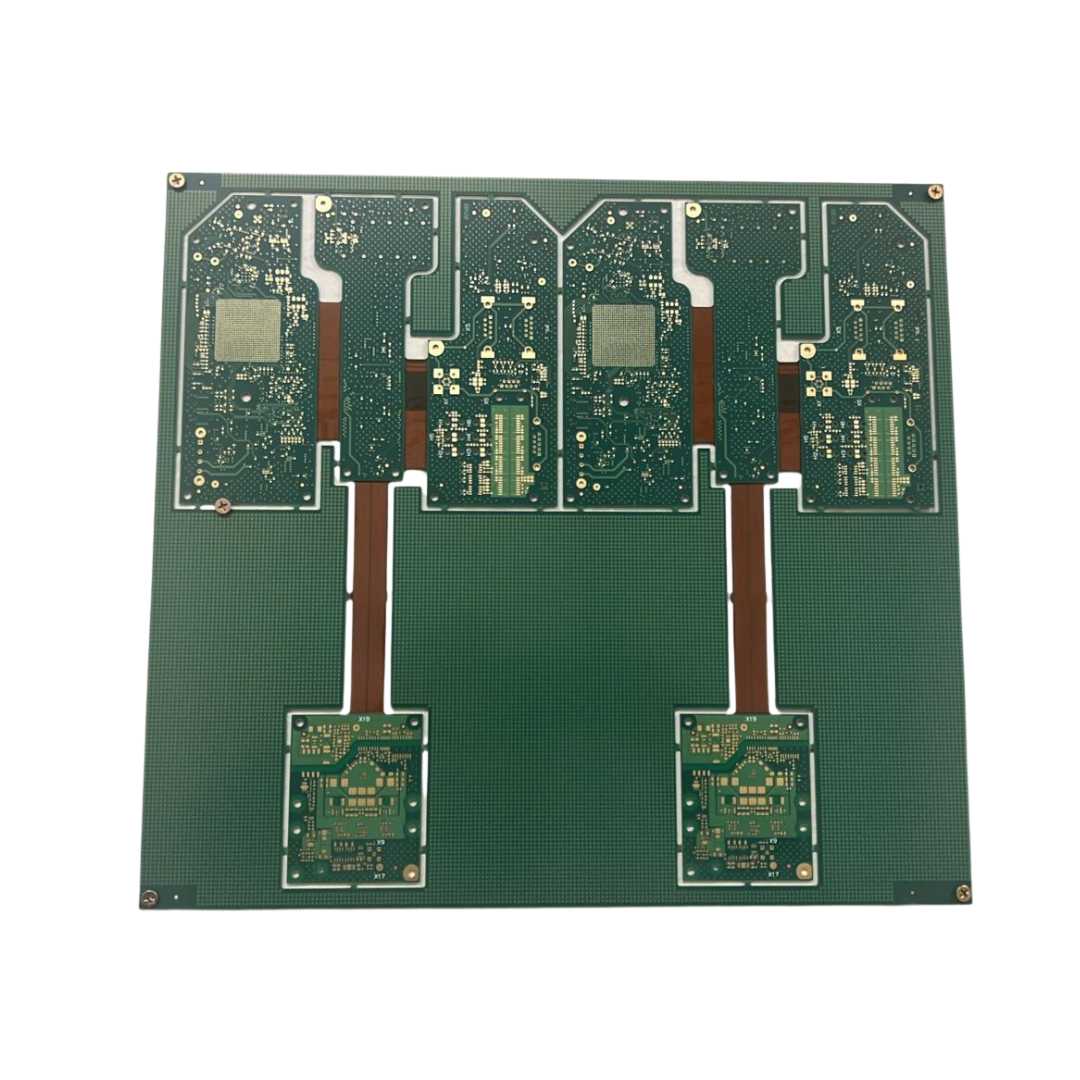

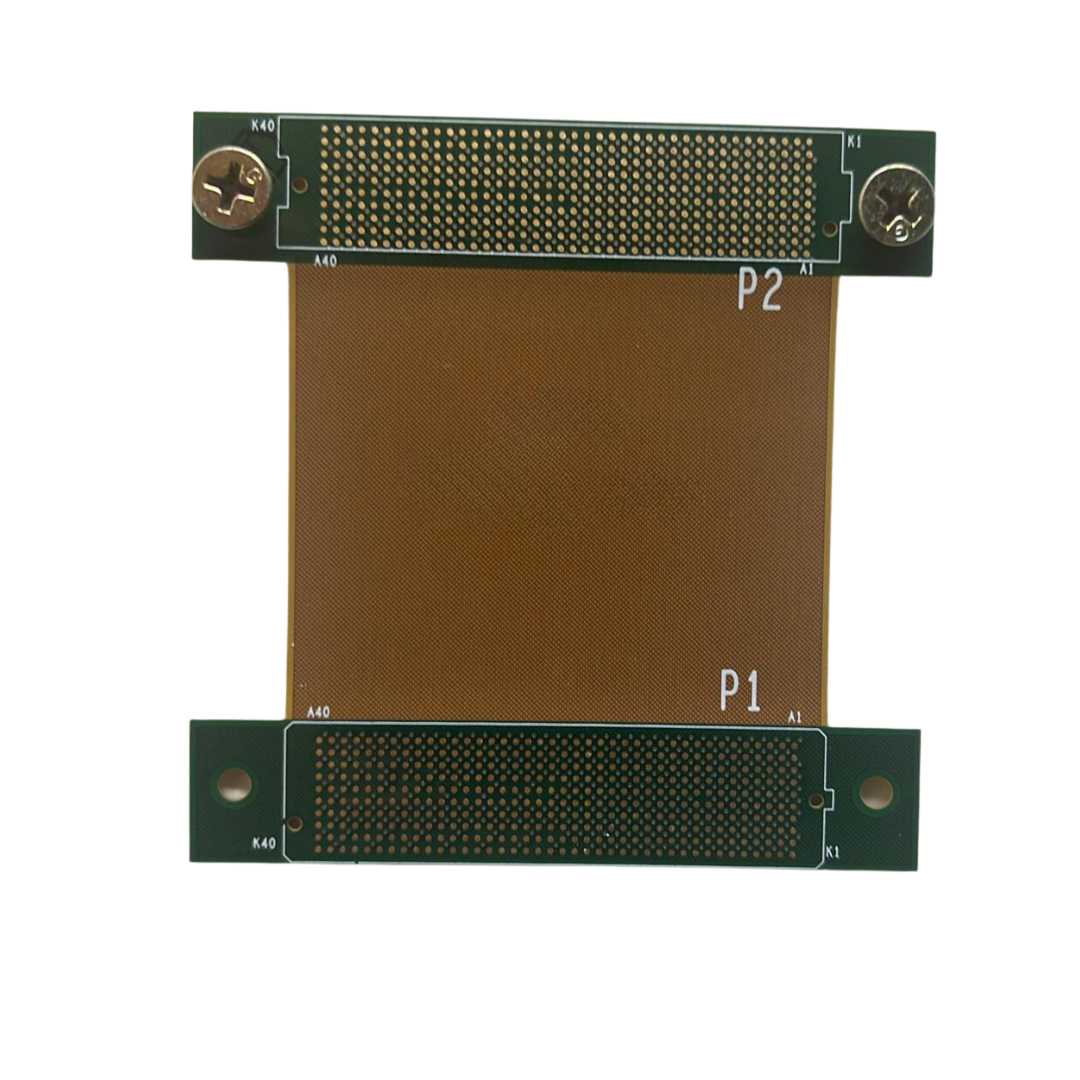

A flexible circuit board is made of flexible materials such as polyimide, polyester, or other similar materials. Further, these boards come with bending and flex features to fit into specific shapes and provide a more efficient use of space.

Where are flex PCBs used?

The top three applications of flex PCB are: medical devices, consumer electronics, automotive components, and more

What is a flex PCB made of?

Flexible PCB is made of polyimide, polyester, polyethylene naphthalate (PEN), polyetherimide (PEI), and, lastly, polyethylene terephthalate (PET).

Why use Flex PCB?

Flexible PCBs are ideal for several applications which require flexibility in frequent movements. Similarly, flex PCBs can provide excellent performance in equipment where high-density interconnections are required.

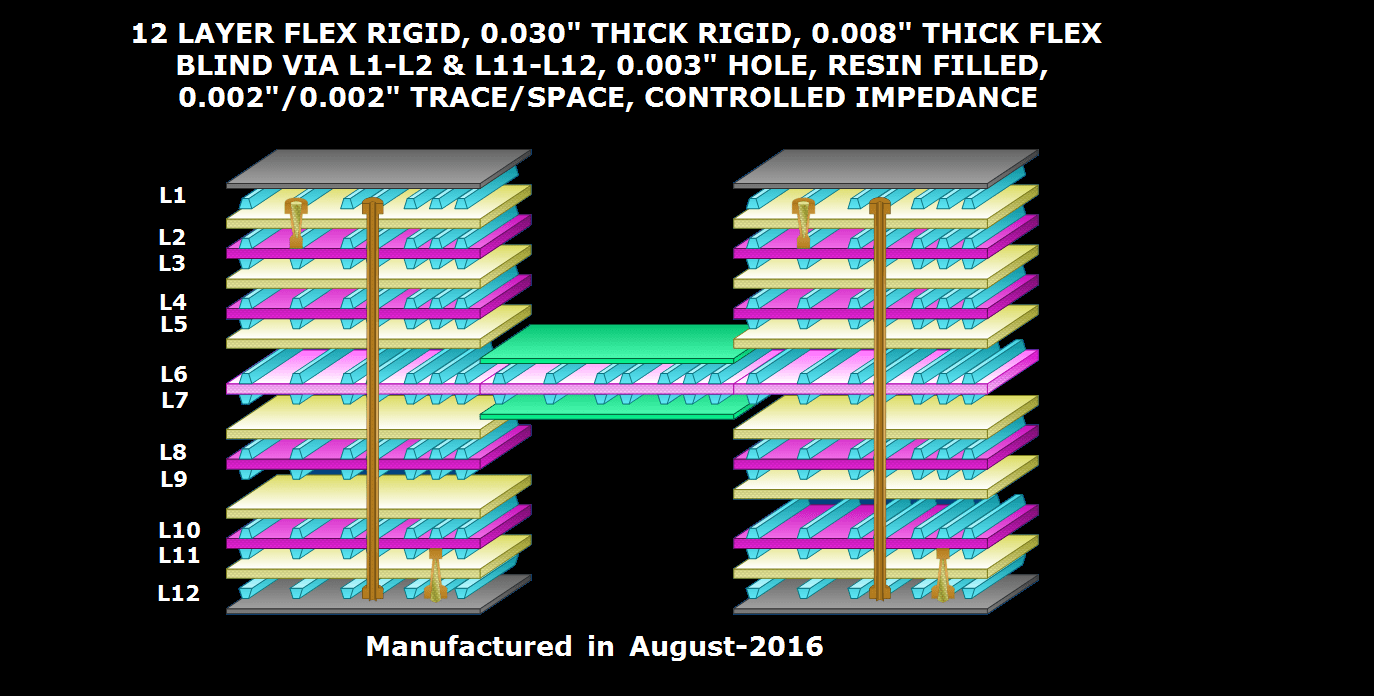

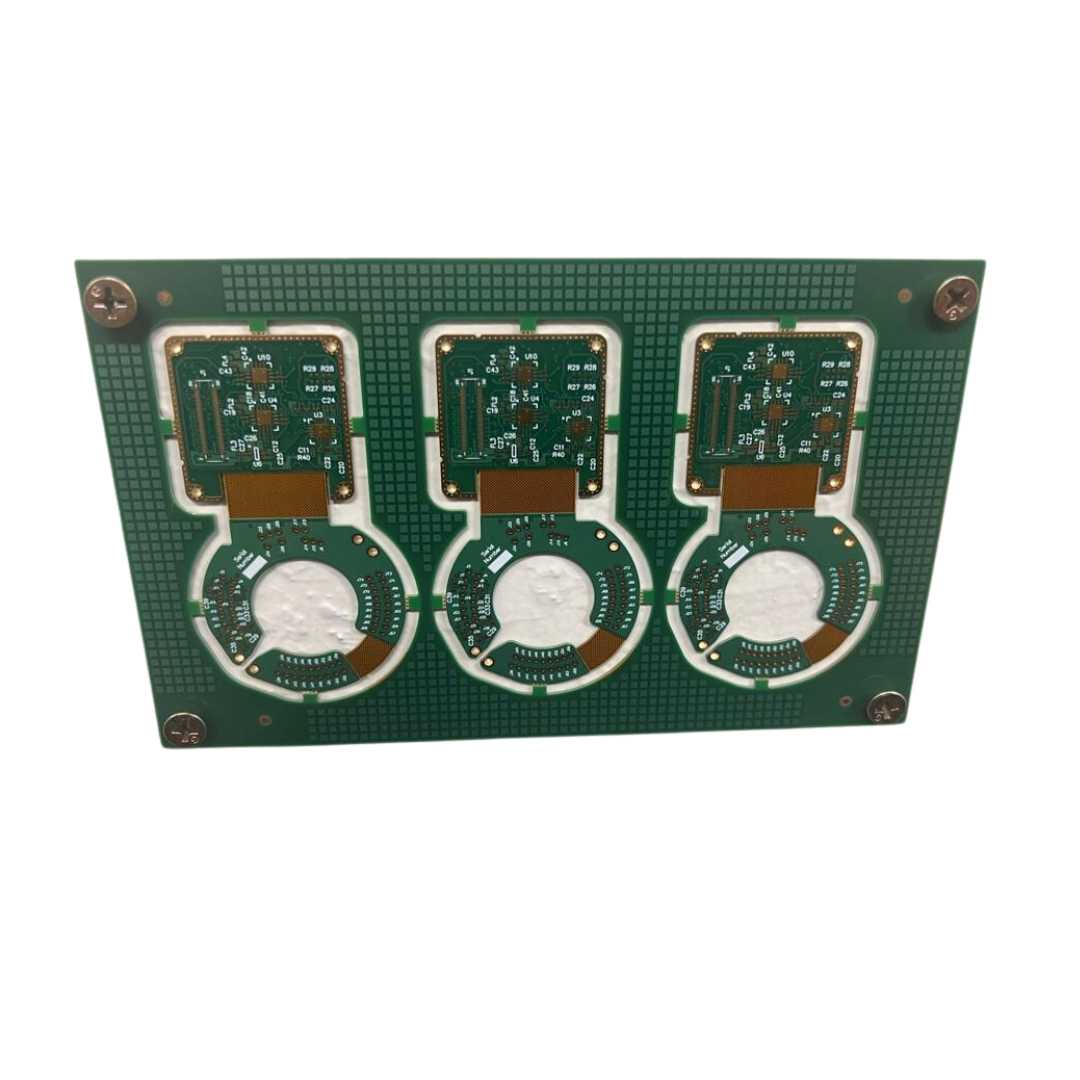

Flex vs Rigid PCB

The basic difference between flex and rigid PCB is the choice of materials and their bending capacity. Comparatively, Flex PCB has flexible characters whereas rigid boards are tight and they are used where design requirements are harder and strong.

What is flexible pcb price?

The price of flexible PCB depends on design, material, and minimum order quantity. So, If you want to get an instant quote for flexible PCB, you can contact our sales department.