Contact us to Get instant Quote for Double sided Flex PCB Online

Don’t hesitate to contact our sales and engineering team; we will provide high-speed PCB prototyping service for flexible circuit boards. So, get a quick quote for your PCB now!

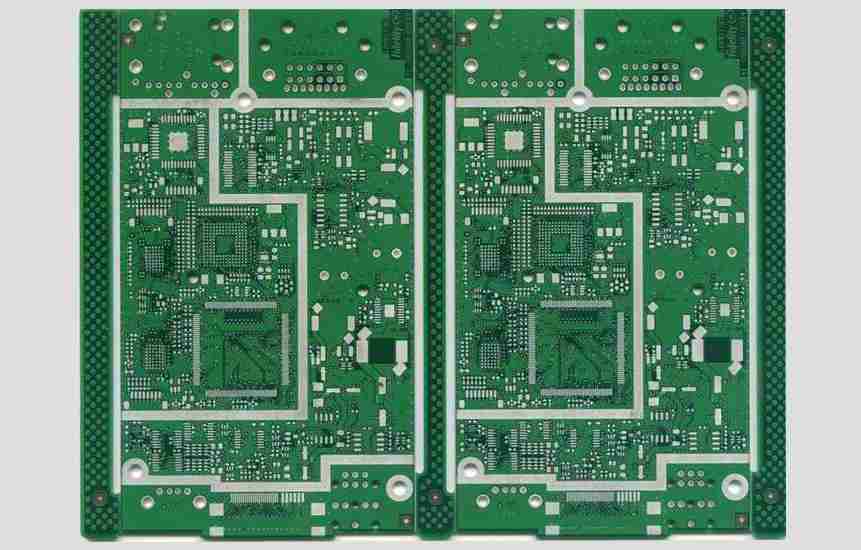

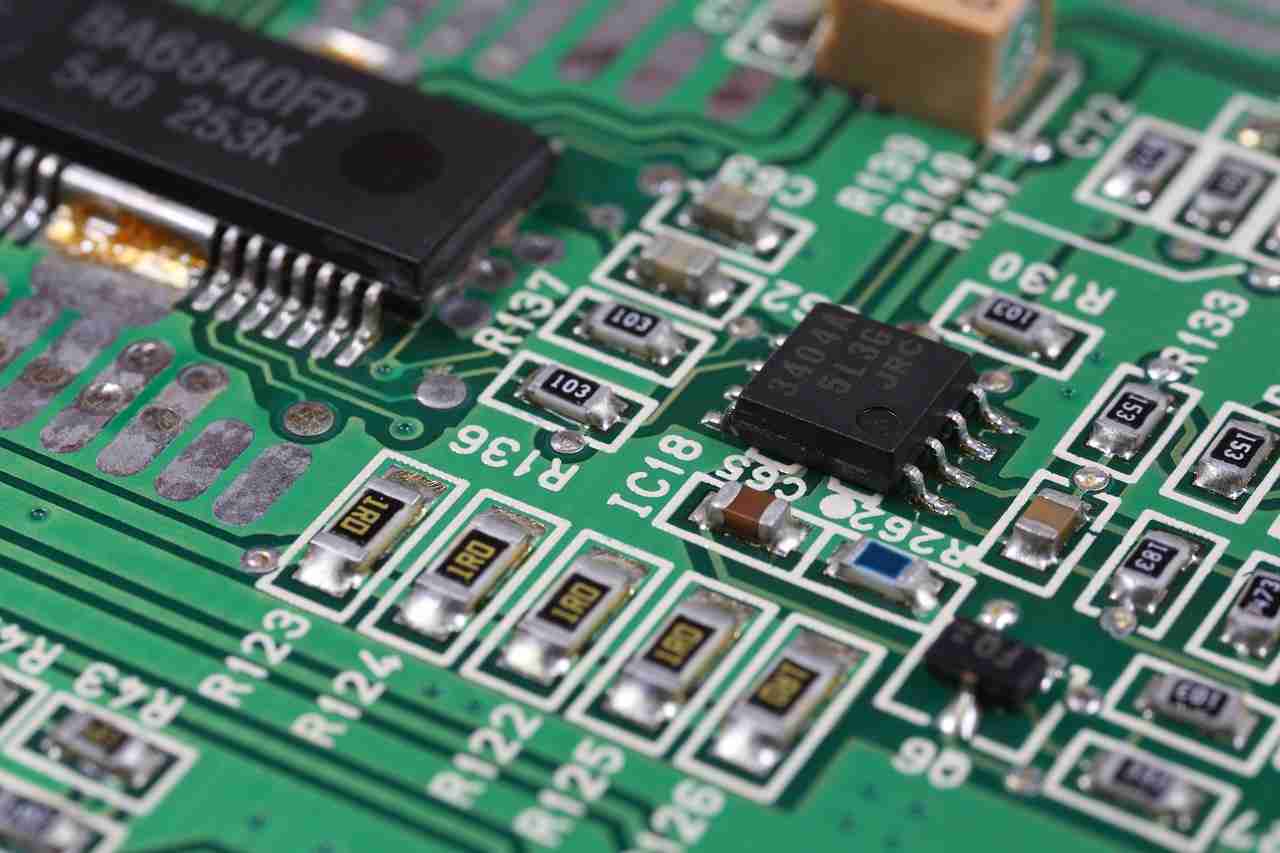

Double-Sided Flex PCBs: Specifications

While designing a flex circuit, you must consider certain specifications. Hence, these specifications will guide your manufacturer on what exactly he must include.

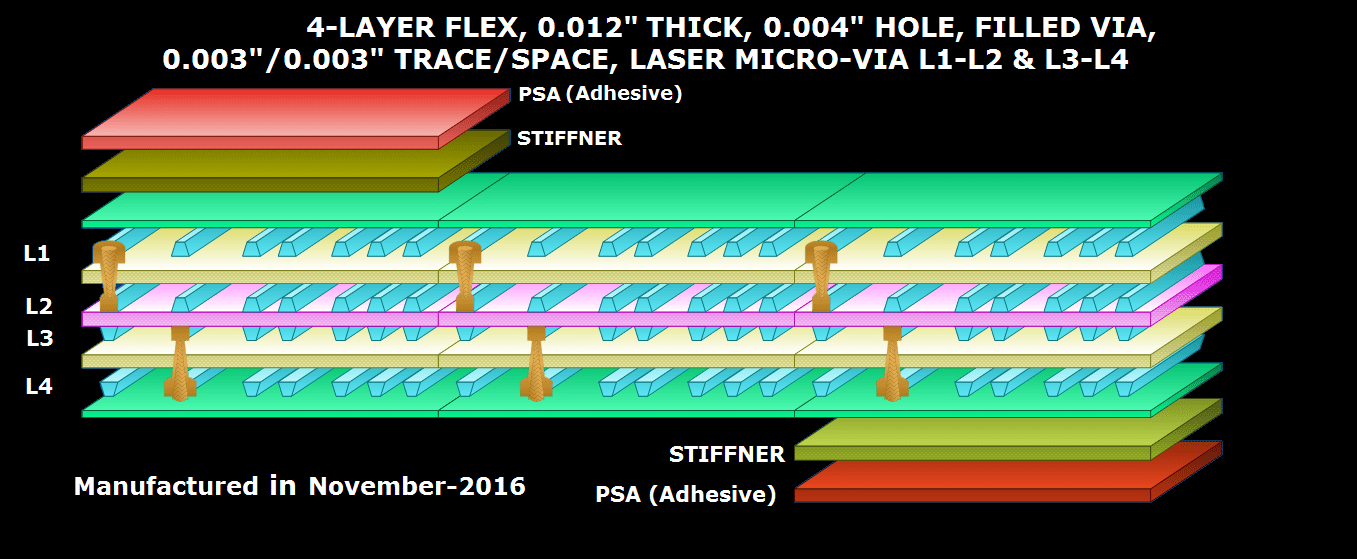

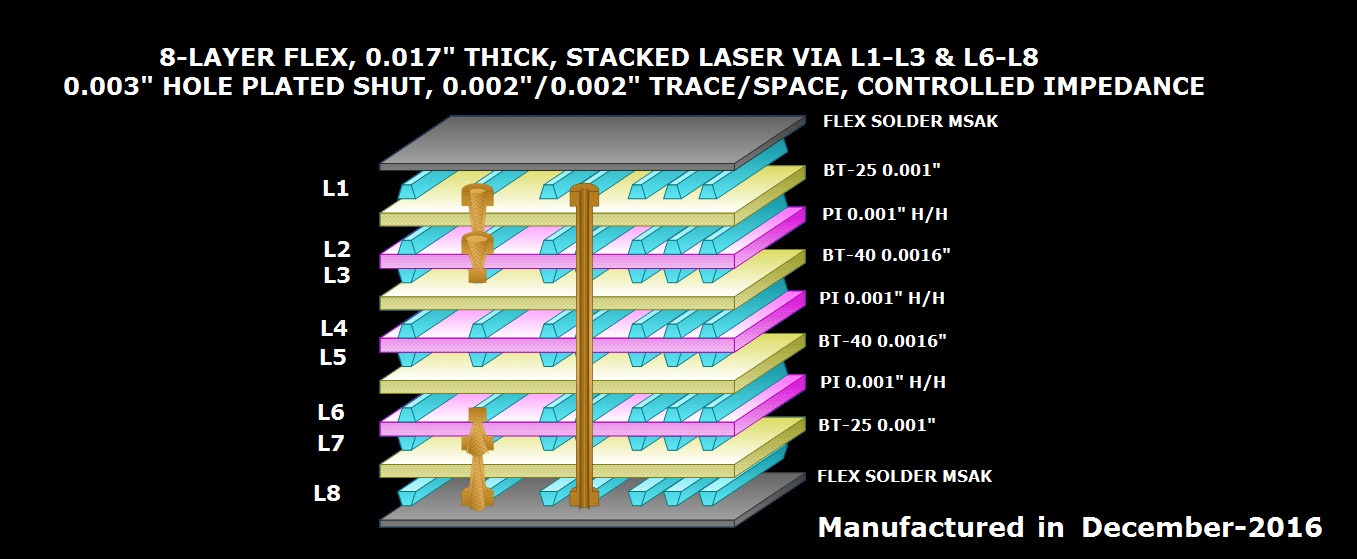

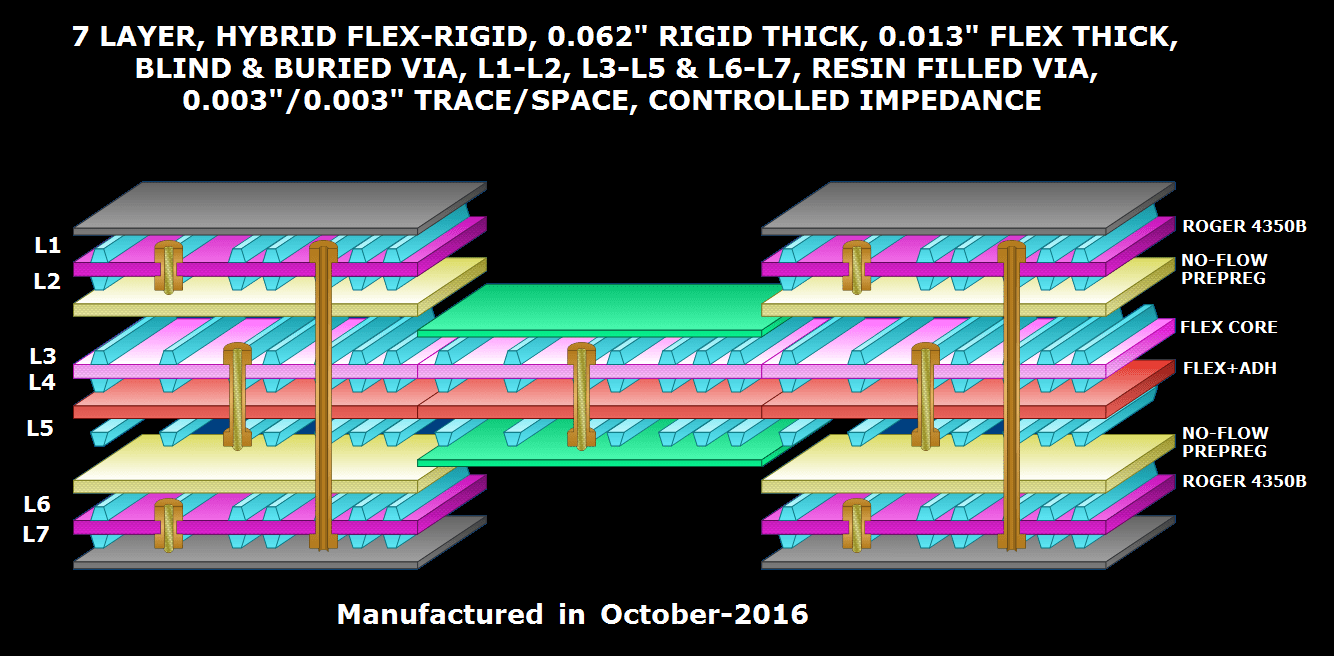

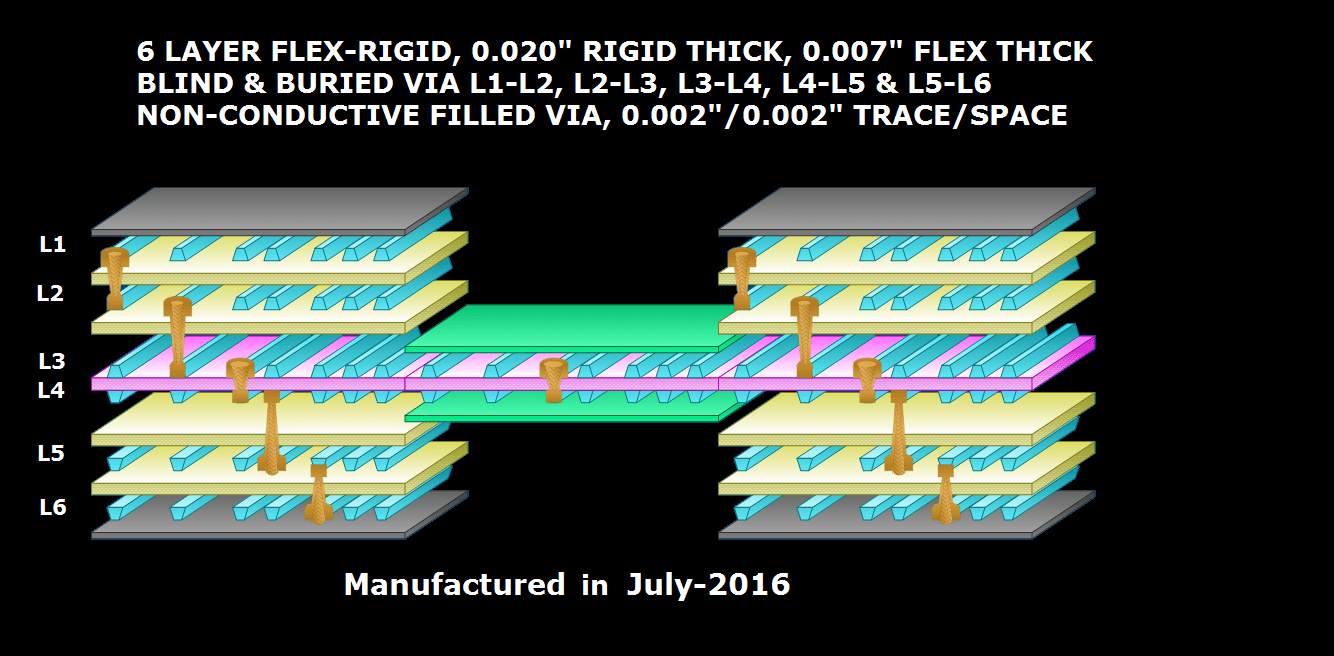

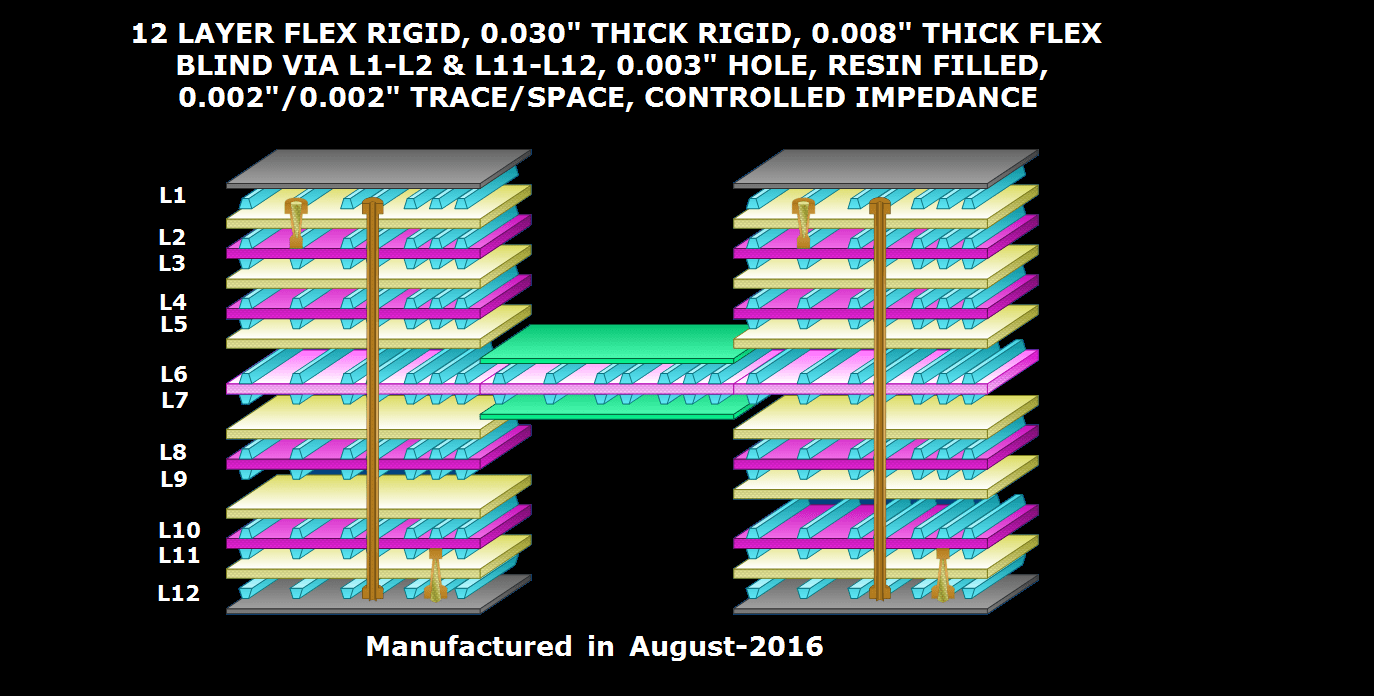

Number of Layers

Since there are different flexible PCBs, you should specify the type you need. Different types of boards have different numbers of layers.

Thus, depending on your specifications, it can have one, two, or more layers.

High TG PCB Board Size

This feature refers to the heat resistance of the material you intend to use in fabricating the flex PCB.

Moreover, you need to specify the type of resistors you need for your design. Thus, this largely depends on the type of material you will choose for your design.

Surface Treatment

There are different forms of surface treatment for you to choose from. Further, there are no specific surface treatments for specific applications.

Hence, this gives you the freedom to choose from the surface treatments available in the industry.