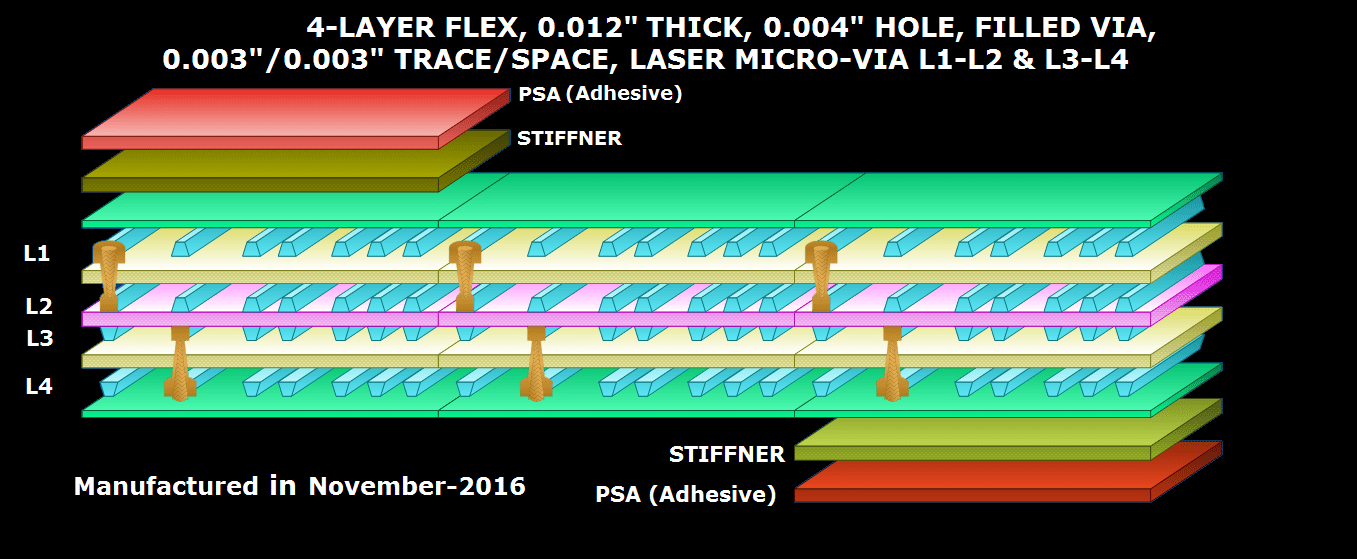

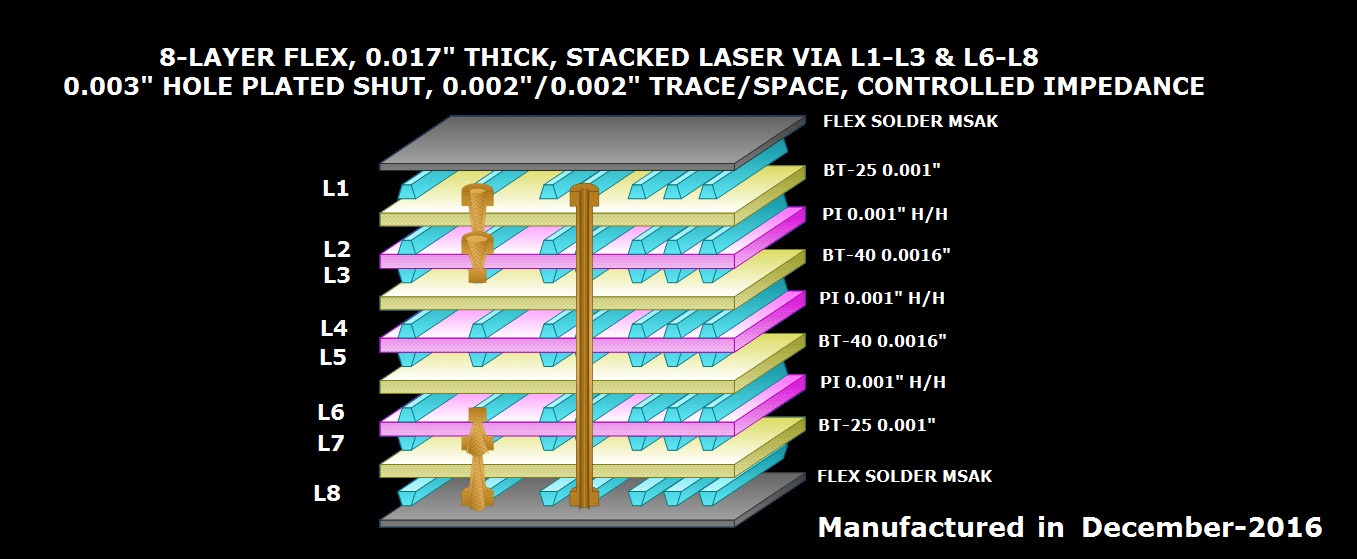

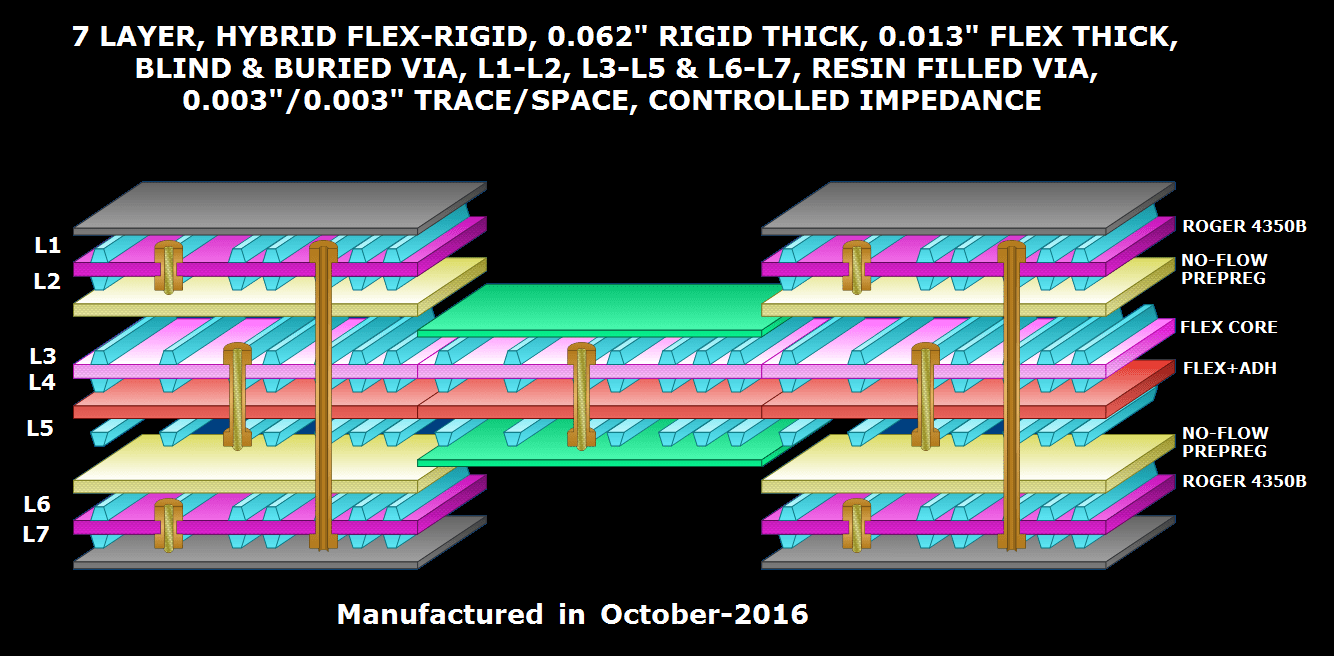

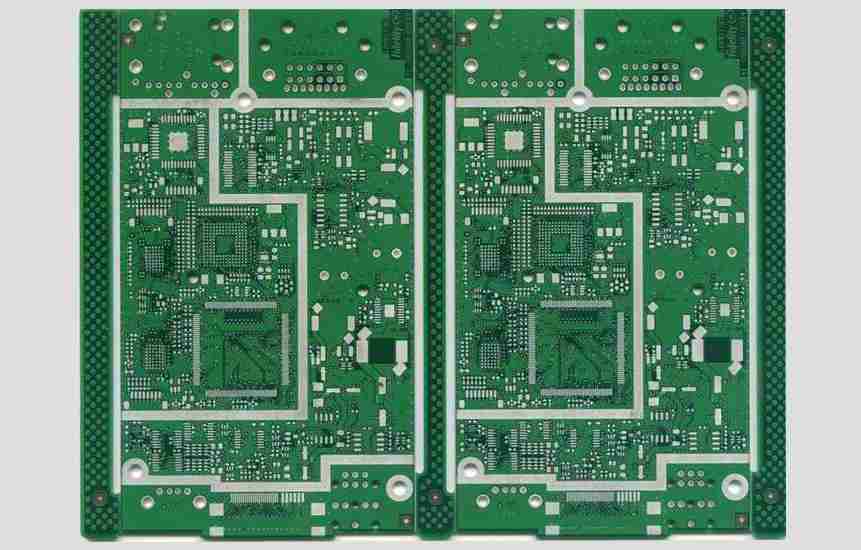

Try RushFlex High-End Solutions to Manufacture Single-Sided Flex PCB

RushFlex provides many physical and electrical interconnection solutions that cannot be achieved with rigid printed circuit board. Compared with standard rigid boards, this additional uniqueness can provide customers with important benefits such as:

- Remove interface connections that may cause reliability issues

- Free up your product’s mechanical space and make your product thinner and smaller

- Reduced package weight and manufacturing costs due to single-board design

- Provide better impedance matching and control

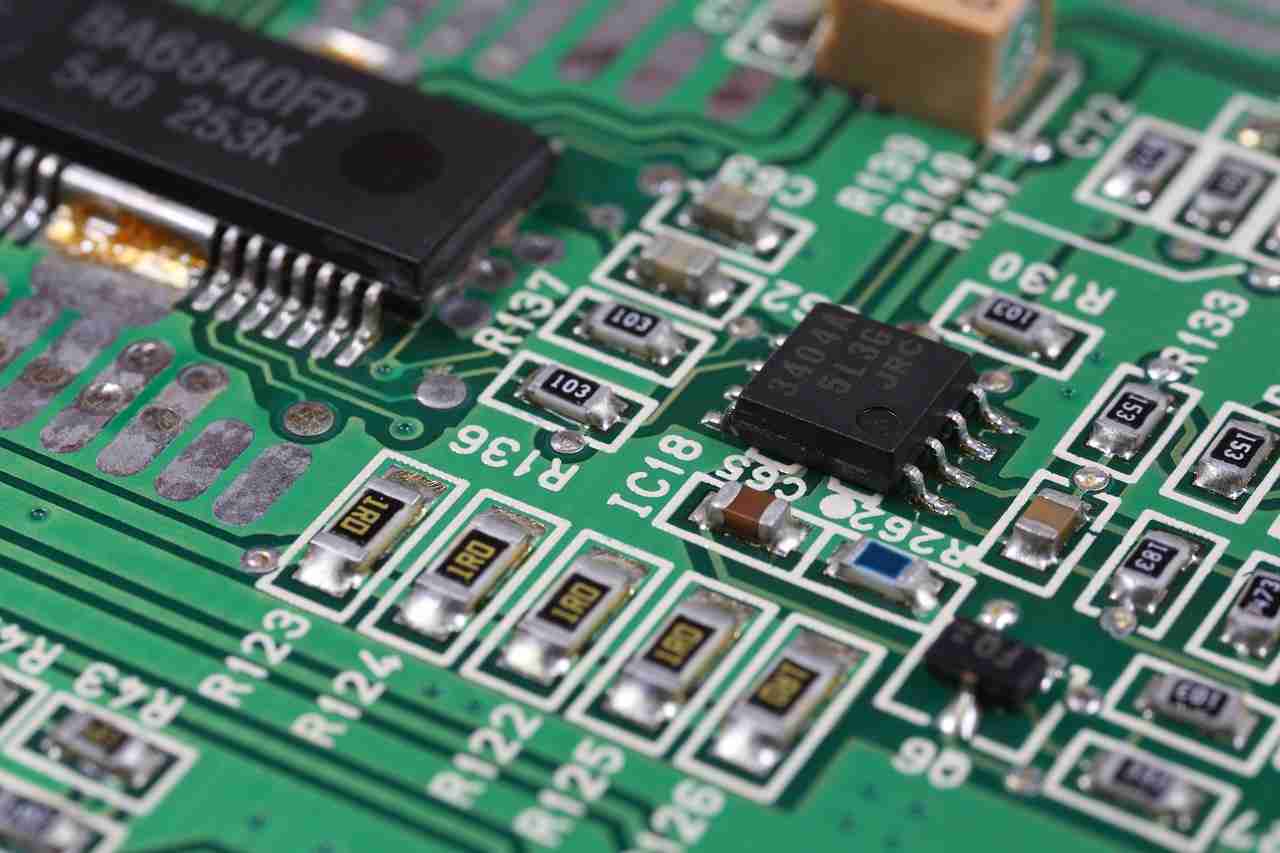

Flexible printed circuit boards range from material development and production, circuit fabrication to final component assembly. RushFlex has vast experience in processing various flexible circuit board materials.