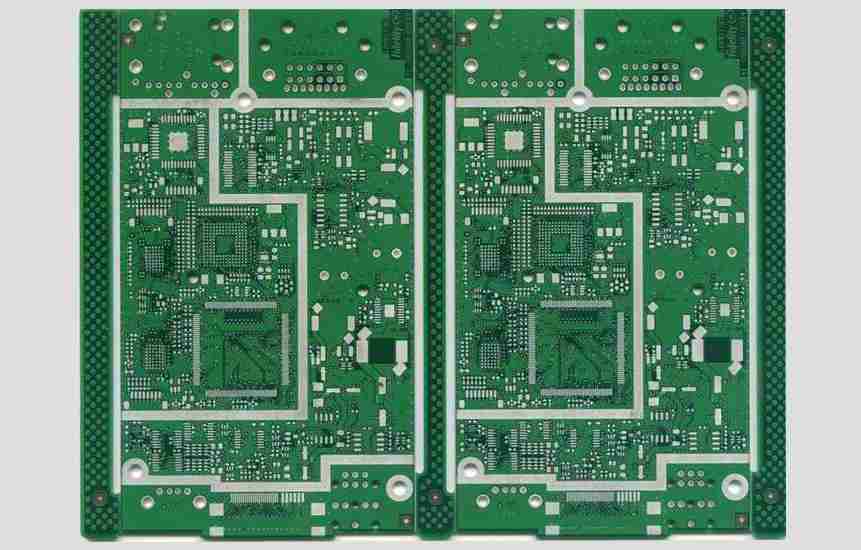

Advantages of Multilayer Flexible PCB

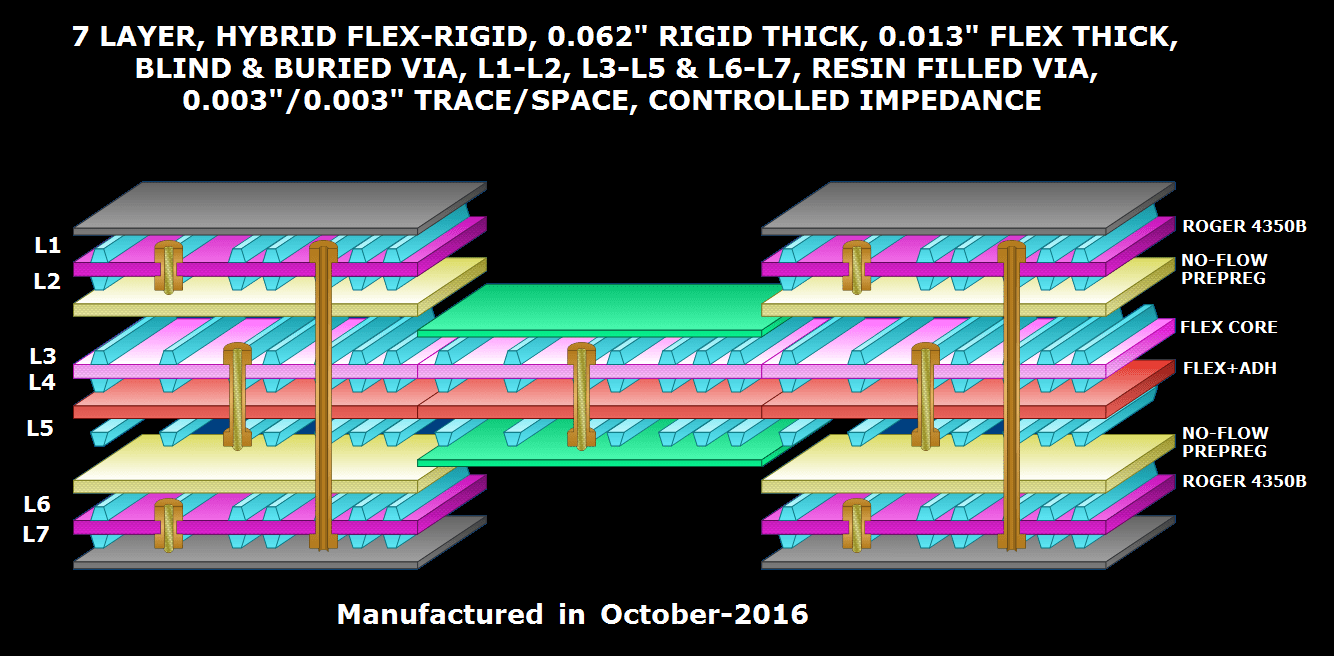

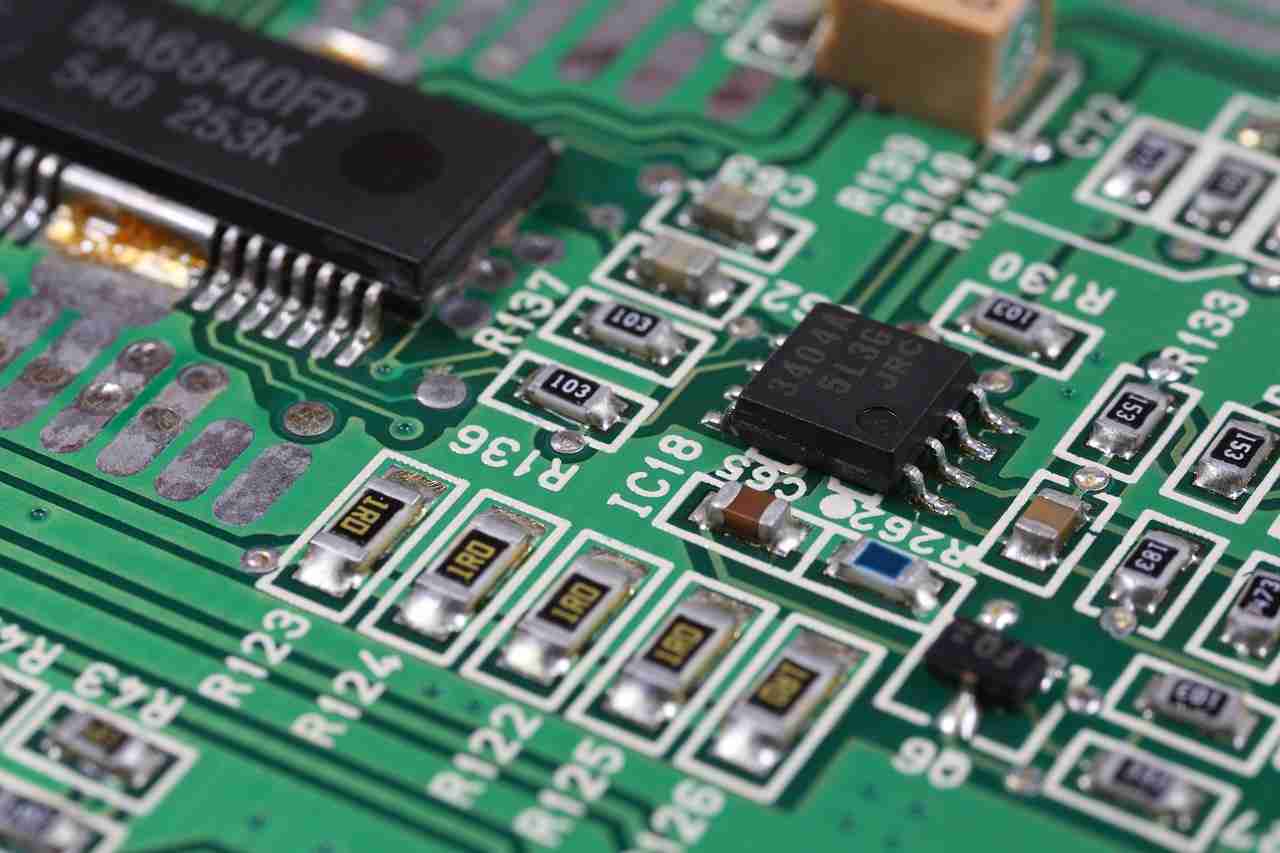

Smaller Size: Due to their layered design, multilayer PCBs are more compact than single-layer PCBs. Consequently, as portable devices like smartphones, laptops, tablets, and wearables continue to shrink while enhancing their processing capabilities, this trend positively impacts the electronics industry as a whole.

Lightweight: Multilayered PCBs are more portable because they eliminate the need for several connectors required by single and double-layered PCBs to communicate with one another. As a result, modern mobile devices reap the benefits of this compact design.

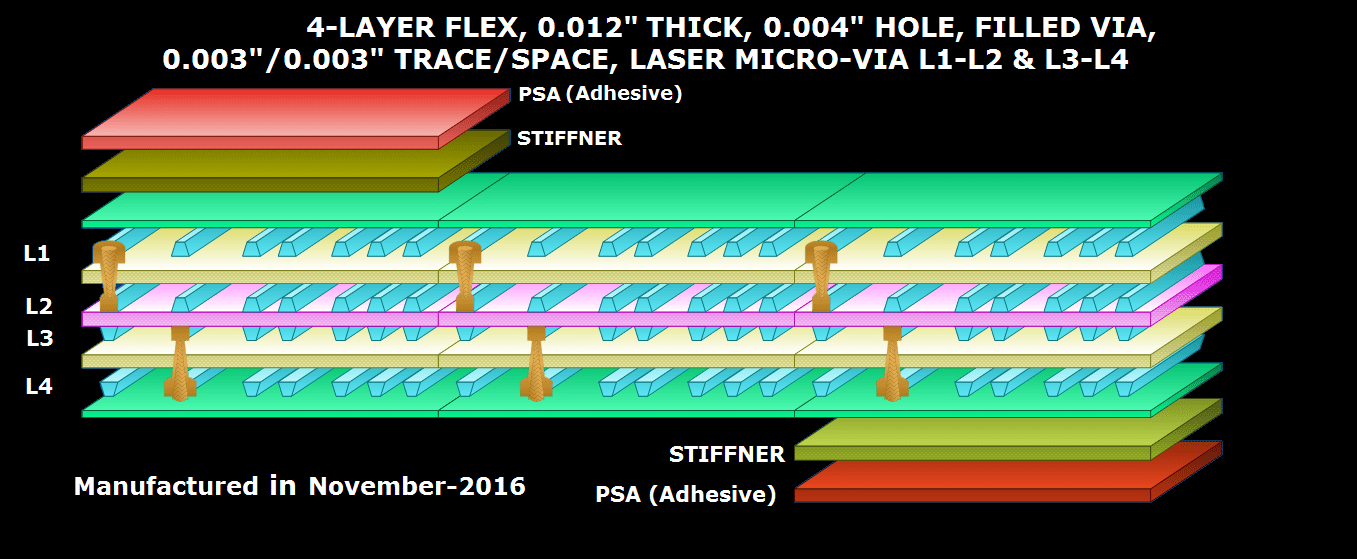

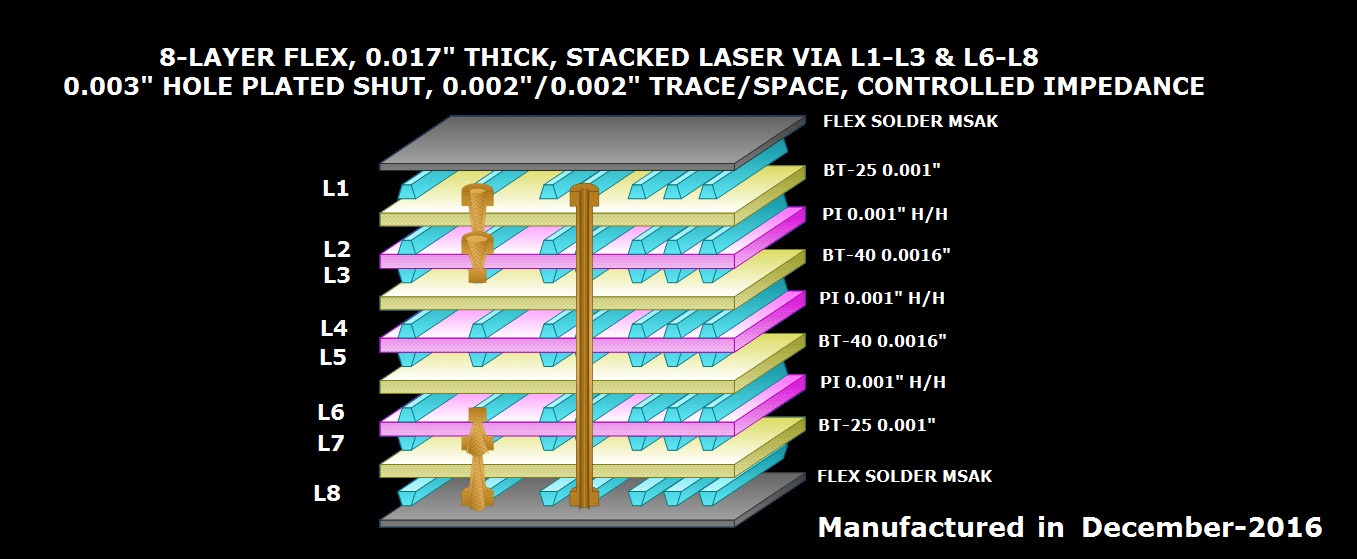

Durability: Printed circuit boards with multiple layers are highly durable. The weight of the individual layers, combined with the heat and pressure used to bond them, ensures excellent performance. Additionally, insulation between the circuit layers on multilayer boards is bonded using a prepreg bonding agent and shielding materials, further enhancing their reliability.

Flexible: Certain multilayer PCB assemblies are highly adaptable due to the methods used in their construction. This makes them ideal for occasional flexing and bending. However, it’s important to note that not all multilayer PCBs are flexible. In fact, the more layers a PCB has, the less flexible it becomes.

Stronger:

Complex multilayer circuit boards (PCBs) consist of multiple layers, which enhance their functionality. Thus, due to their superior electrical properties and compact layout, these boards enable faster communication and provide excellent connectivity.

Comprehensiveness: The functionality of multilayer PCBs operates independently of other parts. They rely on a single connection point rather than multiple single-layer printed circuit boards, simplifying the construction of electronic gadgets. Subsequently, only a single port is required, which significantly benefits miniature, lightweight electronics.